We’re on the verge of a $6.1 trillion technology revolution; embrace it now, so you can capitalize on it in the near future.

April 14, 2017

Sponsored by Barracuda MSP

We’re on the verge of a $6.1 trillion technology revolution; embrace it now, so you can capitalize on it in the near future.

We’re on the verge of a $6.1 trillion technology revolution; embrace it now, so you can capitalize on it in the near future.

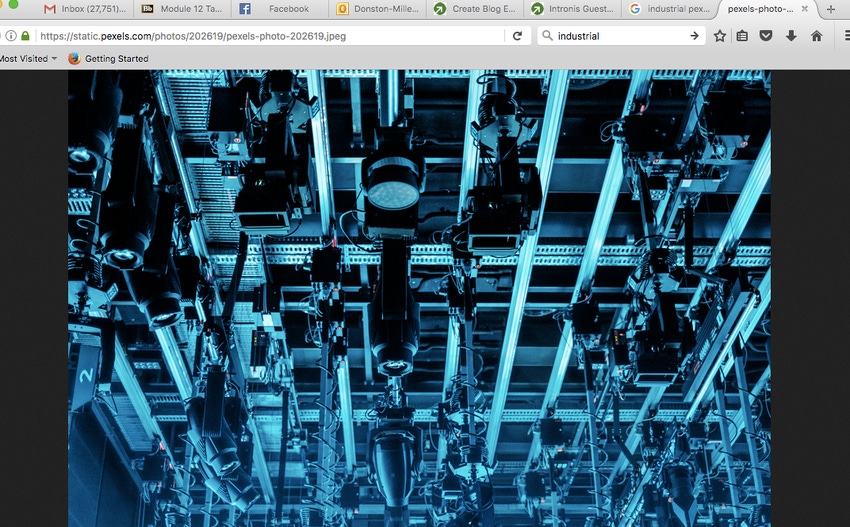

The Internet of Things (IoT), machine-to-machine (M2M) technologies and cloud computing have sparked an evolution in the manufacturing industry, and the monikers being used to describe this merging of technologies and business principles are “Industry 4.0” and the “Industrial IoT (IIoT).” Research from Accenture predicts that Industry 4.0 could add $6.1 trillion in cumulative GDP to the United States by 2030, and MSPs that learn how to adapt their businesses can benefit from this exciting growth opportunity.

Industry 4.0’s Four Design Principles

To better understand all that Industry 4.0 is and what it encompasses, consider the following four foundational pillars that define Industry 4.0:

Interoperability. Machines, devices, sensors, robots, and people connect and communicate via a network, which is sometimes called a wireless sensor network or a wireless body area network.

Information transparency. Businesses gain deep visibility into their operations, product use and asset maintenance requirements, all from a centralized management system.

Technical assistance. Cyber-physical systems (CPSs), which are the next evolution of M2M technologies, can accomplish tasks too difficult, time-consuming or dangerous for humans.

Decentralized decision-making. CPSs embedded with computers or networks have the ability to store and analyze data, which enables them to make decisions with limited or no human intervention.

With an operation that follows Industry 4.0 tenets, a business will have greater insight into its inventory and supply chain, thereby yielding smarter, cost-saving decisions. Businesses can benefit from elevated automation capabilities, as well, such as machines that schedule their own maintenance and applications that automatically perform it. Industry 4.0 also enables self-monitoring products and assets, which can provide location data and details about how they are used and how they operate in various environmental conditions or situations.

Additionally, smart processes can be used to manufacture products tailored to individual customers’ needs just as cost-effectively — or even more so — than products that are mass produced, making custom orders the new norm. When you add up the benefits from better inventory and purchasing decisions, lower labor and administrative costs, and higher-margin products tailored to individual customers’ requirements, it all translates to a healthier bottom line.

The IIoT’s Impact Will Go Beyond Manufacturing

While Industry 4.0’s effect has immediate applications and benefits for manufacturing, its principles can be applied to several other industries and markets as well:

Retail can benefit from enhanced inventory management and visibility, as well as from smart shopping applications that provide insights into consumer behaviors.

Healthcare can apply Industry 4.0 principles to patient monitoring and asset tracking, as well as home healthcare monitoring.

Transportation will find value in new capabilities for fleet management, vehicle diagnostics and freight tracking.

Although Industry 4.0 is about bringing computers and automation to new areas of business and much of the focus is on making decisions with limited or no human intervention, you can be certain that setting up IIoT devices and networks will require human intervention and, more specifically, humans with business and technology expertise. Not only that, once implemented, these devices and networks must be monitored and maintained to ensure their continued uptime, which not surprisingly sounds a lot like the job description for an MSP.

4 Areas MSPs’ IIoT Expertise Will Be Needed

Cisco and Gartner’s report Digital Business Transformation: Disrupt to Win forecasts that 75 percent of businesses will be, or have plans to be, fully digital by 2020. Businesses and enterprises deploying IIoT solutions will need IT expertise and support in the following areas:

Security. To date, most companies’ security strategies involve layering point security solutions as new technology is deployed. The lack of integration and possible security gaps that this approach can create, however, won’t work for Industry 4.0 operations. If hackers can exploit just one device connected to the system, they may be able to exploit the whole network. Industry 4.0 companies will need your expertise to provide a comprehensive security solution.

Bandwidth. With new devices and sensors communicating with the network, there will be a huge increase in network traffic, which will require additional bandwidth and a highly responsive network.

Network availability. With operations relying on CPSs, devices, and machines to optimize productivity, it will significantly lower companies’ tolerance for downtime.

Cloud services. The demands created by Industry 4.0 operations will quickly outgrow most companies’ on-premises infrastructure and platform capabilities. Cloud enables the kind of flexibility and scalability demanded by IIoT applications. MSPs can play an invaluable role in helping customers procure and manage the appropriate cloud services.

Take a Lead Role in Educating Your Customers About Industry 4.0

Your customers and prospects are looking for new ways to use technology to create a competitive advantage and operate more efficiently. Industry 4.0 promises those answers. Rather than waiting to see how things pan out and which devices and software emerge as the de facto standards, why not start now to gain expertise on this topic and then educate your customers about it at quarterly business reviews and other opportune times? After all, you are their trusted business advisor — and this is a $6.1 trillion opportunity.

Chris Crellin is Senior Director of Product Management for Intronis MSP Solutions by Barracuda, a provider of security and data protection solutions for managed services providers, where he is responsible for leading product strategy and management.

Guest blogs such as this one are published monthly and are part of MSPmentor’s annual platinum sponsorship.

You May Also Like